- NYCU Teams Up with U.S. Chipmaker Altera to Launch World’s Largest FPGAi Joint Lab

- NYCU Hosts MEGA DAY as Startups Converge Across the Indo-Pacific

- NYCU College of Nursing Expands Global Footprint with High-Level Exchanges from the U.S., Australia, and the Philippines

- NYCU Partners with Siemens Taiwan and Mega Flow to Build AI-Driven Engineering Simulation Platform

- NYCU and TVGH Announce New Asian Guidelines Lowering Sarcopenia Screening Age to 50

NYCU–Japan Collaboration Unveils World’s First Automated Stem Cell Cultivation System

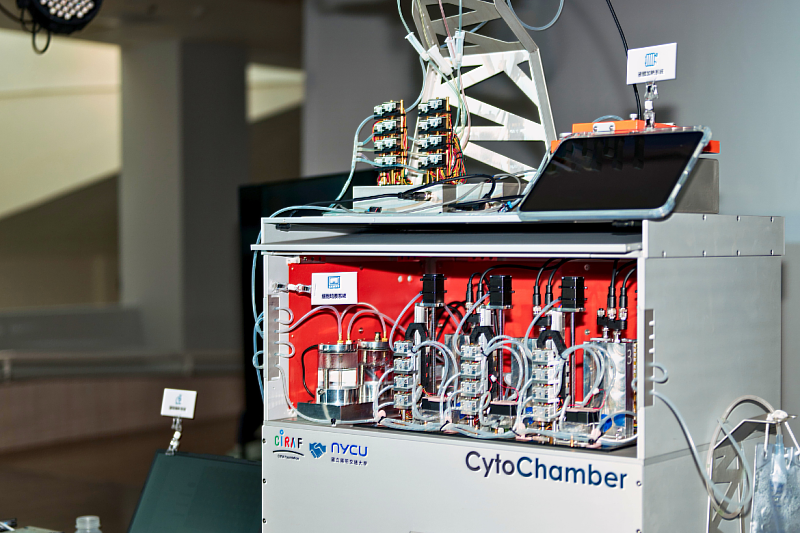

(中央社訊息服務20251218 10:48:35)A Taiwan-led research team has written a new chapter in regenerative medicine. After five years of close collaboration, National Yang Ming Chiao Tung University (NYCU) and the CiRA Foundation at Kyoto University—founded by Nobel Laureate Shinya Yamanaka—have unveiled the world’s first fully automated system capable of cultivating and differentiating stem cells: the Cyto Chamber (Pioneer One).

The milestone marks a significant advance in stem cell manufacturing and highlights the growing impact of Taiwan–Japan scientific collaboration at the intersection of engineering and medicine.

Stem cells possess the potential to differentiate into a wide range of tissue types, making them a cornerstone of regenerative medicine. However, their preparation has long been constrained by labor-intensive procedures, high costs, and inconsistent quality caused by heavy reliance on manual operations.

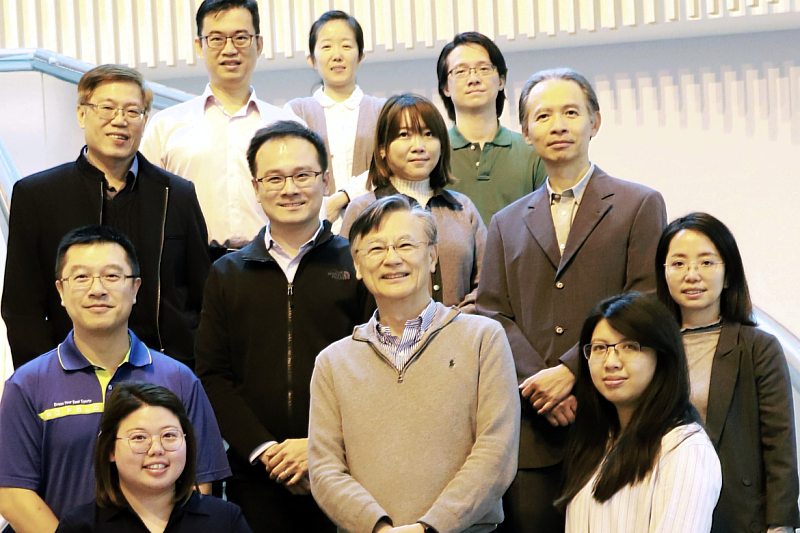

To overcome these challenges, Taiwanese and Japanese researchers launched a joint effort five years ago. NYCU became the only Taiwanese partner in the CiRA Foundation’s global “my iPS Project,” with a shared goal of overcoming the technical barriers to large-scale stem cell production and quality control.

Beyond engineering, NYCU’s interdisciplinary strengths—spanning remote sensing, AI, earth sciences, electronics, and data analytics—position the university as a comprehensive ecosystem for future space talent.

NYCU and the National Center for Instrumentation Research, under the National Applied Research Laboratories, jointly developed the Cyto Chamber (Pioneer One). The system fully automates stem cell cultivation and passaging, integrating temperature regulation, carbon dioxide control, culture medium supply and removal, and continuous microscopic imaging into a single platform.

Processes that previously required extensive human labor can now be executed with high efficiency and reproducibility. The system represents a critical step toward the industrialization of regenerative medicine and scalable cell manufacturing.

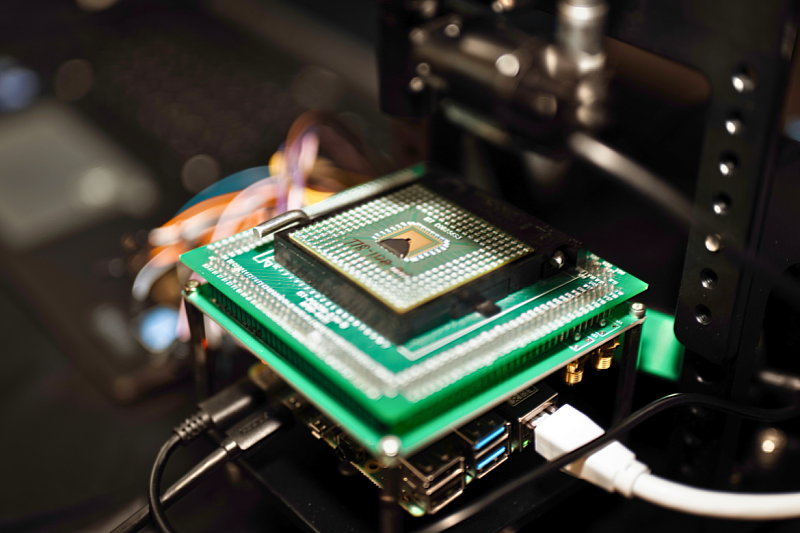

Beyond automation, NYCU’s semiconductor chip engineering team has developed an innovative QC Chip (Quality Control Chip) to address another long-standing challenge: stem cell quality assurance.

Unlike conventional inspection methods that rely on antibody labeling, the QC Chip applies electronic engineering technologies to monitor stem cell quality in real time. This approach significantly shortens testing time while enhancing consistency and stability—key requirements for clinical and industrial applications.

The Cyto Chamber and QC Chip were recently unveiled at the CiRA Foundation in Japan, immediately drawing strong interest from Japanese industry leaders and research institutions. The debut highlighted the success of Taiwan–Japan cross-border collaboration and showcased NYCU’s distinctive ability to integrate engineering innovation with biomedical research.

Describing the achievement as “a perfect convergence of engineering, medicine, and chip technology,” NYCU President Chi-Hung Lin said Taiwan’s combined strengths in biomedicine and semiconductor engineering were a key reason Japanese partners chose Taiwan as a collaborator. The system, independently developed by a Taiwanese team, not only validates the original vision behind NYCU’s university merger, Lin noted, but also demonstrates Taiwan’s scientific and technological capabilities on the global stage.

Looking ahead, Lin emphasized that the maturation and future mass production of the Cyto Chamber and QC Chip will enable regenerative medicine to move beyond laboratory research and into industrial and clinical applications. “This cross-border scientific journey is laying the foundation for new medical possibilities in the decade ahead,” he said.

Five years ago, NYCU was entrusted by its Japanese partners with developing an automated stem cell platform. This effort led to the stationing of Japanese researchers in Taiwan for long-term collaboration. What once seemed an impossible mission has now been realized.

The achievement was made possible in part by support from Taiwan’s Ministry of Education's Higher Education Sprout Project and the National Science and Technology Council’s research commercialization programs, opening new opportunities for the globalization and industrialization of stem cell manufacturing in Taiwan.